Posts

Showing posts from January, 2017

Quick Packaging News: Stretch Film and Plastics Pricing News

- Get link

- X

- Other Apps

Quick Packaging News: Stretch Film and Plastics Pricing News

- Get link

- X

- Other Apps

Stretch Film and Plastics Pricing News

- Get link

- X

- Other Apps

NEWSWIRE SNIPPETS Our polyethylene resin suppliers have informed us of a new resin price increase effective February 1st. Factors supporting this resin increase are; improving domestic and global demand, rising feedstock costs. In response to this February 1st resin increase, all new orders received on or after February 24th will be priced at a 7% increase. U.S. Stretch Film Producer January 2017 ( Read Sigma letter ) MARKET BEAT Alcoa reported higher-than-expected revenue in its first quarterly results, helped partly by a rise in alumina prices. Alcoa said it expects a 6% increase in demand from China, driven by packaging, electrical, transportation sectors. "Rising aluminum prices improved the bottom line," the company said in a statement, adding that margins doubled in one segment. Aluminum prices climbed to a 20-month peak yesterday after reports of potential capacity cuts in China. Trade Reports January 2017 RESPECTED MARKET ANALYST REPORTS TODAY January LLDPE rol...

Quick Packaging News: How to Improve your Bottom Line?

- Get link

- X

- Other Apps

How to Improve your Bottom Line?

- Get link

- X

- Other Apps

Want to improve your bottom line? The answer is closer than you think Cost and efficiency: the mere mention of these two words is enough to see any manufacturer break into a cold sweat. They are the two forces that impact every manufacturing sector. So how can manufacturers successfully optimize cost and efficiency to improve their bottom line? Manufacturers are under growing pressure to improve efficiency and lower costs. Traditionally this has meant struggling to find the delicate balance between cost-cutting and product quality. This is made even more complex with the high line speeds and frequent line changeovers – both of which are becoming more common as manufacturers keep trying to push productivity to the limits. A large part of the solution lies in internally optimizing processes and equipment. To see how this works in action, let’s take the example of end of line packaging equipment: 1. Reduce total cost of ownership (TCO) You can save money, increas...

Quick Packaging News: Resin and Plastics Pricing News

- Get link

- X

- Other Apps

Resin and Plastics Pricing News

- Get link

- X

- Other Apps

Nova Chem. new LLDPE reactor up and running prime grade resins, just one of many major resin producing plants (U.S.)coming on stream in 2017. Trade Reports January 2017 LLDPE selling activity up (film grades) in the U.S. with pricing heading north. Market fundamentals showing some support for 5c/lb Feb increase. Trade Sources January 2017 More information at this space: www.quickpakinc.com

Product recall or withdrawal?

- Get link

- X

- Other Apps

Product recall or withdrawal? Fact’s every company should know. Let’s say the unthinkable has happened: you’ve discovered a problem in your manufacturing line that affects a whole batch of products. Worse still, a full supply has already left the plant and hit the store shelves. What now? Is it a “recall” or a “withdrawal”? Does it matter? Yes, it really does — and this is why: if you issue a recall notification but it’s actually a product withdrawal, you could find yourself paying out for media notices and other recall costs for no reason. On the other hand, if it’s a recall and you treat it as a withdrawal, the ramifications could extend to legal action. Knowing the difference between a recall and withdrawal means you can handle the situation quickly and correctly, saving you valuable time, money and stress. Here’s a guide we’ve put together on the key differences between a “product recall” and a “product withdrawal” that every manufacturer and brand owner should know....

Quick Packaging News: Direct Thermal Print or Thermal Transfer Labels fo...

- Get link

- X

- Other Apps

Direct Thermal Print or Thermal Transfer Labels for Barcodes?

- Get link

- X

- Other Apps

So should you choose direct thermal print or thermal transfer labels to print barcodes? There’s a misconception in the industry around these technologies: many people believe that direct thermal (because it has no ribbon) is a less expensive option than thermal transfer. But don’t be caught up there: it’s critical to first understand which technology is more efficient for whom. The bottom line: The cost difference between the two is negligible — until you start looking at what happens to your product after it leaves your factory floor. Before you buy any equipment , make sure you know the pros and cons of both technologies. Direct transfer labelling systems: no ribbon, lower contrast At first glance, it seems cheaper to not require a ribbon in your direct transfer labelling system. But “whether you save on ribbon costs” is the wrong question to ask when you’re assessing this technology. Think about these things instead: Your label’s edges and the te...

Revolution Airflow FR Pallet Wrapper FREE with Airflow Film

- Get link

- X

- Other Apps

Quick Packaging News: Product identification and traceability innovation...

- Get link

- X

- Other Apps

Product identification and traceability innovation

- Get link

- X

- Other Apps

Both product identification and traceability are used across a range of different industries, each of which has its own unique set of labelling requirements. The one you choose largely depends upon the sector your business operates in – from food and produce to automotive parts and pharmaceuticals. The food processing industry tracks the journey of food using barcodes and RFID tags . This is a compulsory exercise which was brought about by the EU General Food Law in 2002. The year 2004 saw innovative technology used in tracing animal products, with the advent of the EU TRACES database system, which tracks animals from birth to the abattoir. The food industry in general, can be broken down into several categories including baked goods, fresh produce and frozen food – each of which has its own product identification and tracking requirements. Different foods have different packaging needs to cater for freshness and transportability. For crisp packets and cardboard boxes through...

Quick Packaging News: What you need to know about preventive maintenance...

- Get link

- X

- Other Apps

What you need to know about preventive maintenance vs breakdown repair.

- Get link

- X

- Other Apps

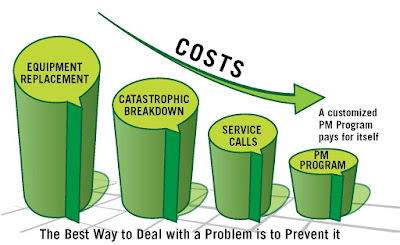

You know what they say: “If it ain’t broke, don’t fix it”. For decades, many manufacturers have relied on a “fail and fix” approach for packaging equipment, waiting until the very moment it breaks down before fixing the problem. However, there’s a growing school of thought that an alternative “predict and prevent” approach is the best — and perhaps only? — Way to run a production line. So which should you choose? Here we look at the pros and cons of each approach: What is preventative maintenance? Preventative maintenance, or planned maintenance, is the process of making sure that all packaging equipment is operating at peak efficiency at all times. Depending on the equipment, it may comprise quick daily inspections, cleaning, lubricating and minor adjustments. In the short term, this means minor problems can be detected and solved before they become a major problem. And in the long term, preventative maintenance helps you get the most from your equipment for long...

Quick Packaging News: Packaging Equipment Preventative Maintenance

- Get link

- X

- Other Apps

Packaging Equipment Preventative Maintenance

- Get link

- X

- Other Apps

Packaging Equipment Preventative Maintenance Keeps it running! Stretch wrappers, Case Erectors, Shrink Wrappers, Case Sealers, Strappers, Tapers- you name it, these are all very complex pieces of packaging equipment expected to optimize your production line for efficient packaging processes. If maintained properly, these machines can last years without any problems or breakdowns. Periodic maintenance is important. Most companies search for major causes that could be responsible for the problems, yet overlook the minor causes that contribute to the big problem. To ensure that your business model can be upheld in the long run, it’s important to follow up and check on the reliability of your machines. Inspecting your machines can reduce the likelihood of any disastrous maintenance issues that might arise unexpectedly. After all, it’s much easier, less stressful, and less costly to prevent problems than it is to interrupt workflow to repair them. A lack of prev...

Quick Packaging News: Lowest Tape Price with FREE Shipping

- Get link

- X

- Other Apps

Lowest Tape Price with FREE Shipping

- Get link

- X

- Other Apps

2" X 1.8MIL X 110YD CLEAR ACRYLIC TAPE FREE Freight on 90 case order. Clear Acrylic Bander brand tape will perform in a wide range of temperatures (32 degrees - 120 degrees), Bander tape crystal clear to not interfere with exterior markings and labels, and instantly bonds to corrugated boxes and surfaces. Bander Tape comes in hand grade for manual application. Bander Tape water based acrylic carton sealing tape is made with a special high-shear adhesive, developed specifically to meet our rigorous specifications. Higher shear values mean greater holding power on boxes. Your Price: $23.00/case delivered on pallet orders . Buy here: www.quickpakinc.com

Quick Packaging News: Best Way to Wrap and Stack Product on a Pallet

- Get link

- X

- Other Apps

Best Way to Wrap and Stack Product on a Pallet

- Get link

- X

- Other Apps

In the United States, our freight is shipped on an estimated 1.4 billion pallets in active circulation. Wrapped Pallet by Quick Pak Inc More companies are palletizing freight for delivery because it’s an easy way to cheaply transport large items. There is also less chance for items to be damaged when being delivered on a pallet. That’s because they are handled by fork lift trucks rather than boxes possibly being thrown from one man to another! But to ultimately end up at its destination without damage, the pallet must be properly packed. Here are some tips on how to pack a pallet. Choose the right pallet: It should be large enough so that your shipment does not overhang the edges. Pallets should be sturdy enough to support the load. Avoid pallets with broken boards or protruding nail heads. Stacking on the pallet: Make sure cartons are new and of proper strength to withstand stacking. Stack smaller, lighter items on heavier items. Securel...

Quick Packaging News: 2" X 1.8MIL X 110YD CLEAR ACRYLIC TAPE

- Get link

- X

- Other Apps

2" X 1.8MIL X 110YD CLEAR ACRYLIC TAPE

- Get link

- X

- Other Apps

FREE Freight on 98 case order @ $24.99/case delivered. Clear Acrylic Bander brand tape will perform in a wide range of temperatures (32 degrees - 120 degrees), Bander tape crystal clear to not interfere with exterior markings and labels, and instantly bonds to corrugated boxes and surfaces. Bander Tape comes in hand grade for manual application. Bander Tape water based acrylic carton sealing tape is made with a special high-shear adhesive, developed specifically to meet our rigorous specifications. Higher shear values mean greater holding power on boxes. SKU: Bander Your Price: $24.99/case delivered.

Revolution ST Pallet Stretch Wrapping Machine with FREE Pallet of Wrap

- Get link

- X

- Other Apps

Quick Packaging News: Printed Pallet Wrap from Quick Pak Inc

- Get link

- X

- Other Apps

Printed Pallet Wrap from Quick Pak Inc

- Get link

- X

- Other Apps

Printing capacity increased: Quick Pak now offers lower minimums and faster lead times on all printed films. Advertise: Logo's, name, website, re-ordering info, etc... Safeguard Shipments: Printed message make handling requirements highly visible. "Do Not Double Stack", "Fragile", "Handle With Care", "Do Not Break Pallet", "Signature Required", "Keep Frozen" Security Appeal: Reduces risks of pilferage and tampering in storage or transit. Easily identify shipments that have been broken into or tampered with. Reduce Lost Shipments: Easier to identify pallets means carriers are less likely to misplace or lose shipments. See examples and order here.

Quick Packaging News: Roping Stretch Film Will Increase Load Holding Pow...

- Get link

- X

- Other Apps

Roping Stretch Film Will Increase Load Holding Power

- Get link

- X

- Other Apps

Roping Stretch Film Will Increase Load Holding Power. Roping pre-stretched film provides an economical and efficient method to wrap organic products without limiting load stability. Stretch wrapping of pallets has become standard practice across many industries, including the shipment of food products to grocery retailers. Secure pallet load unitizing is most often achieved by stretch wrapping a pallet load in pre-stretched film, providing not only unit strength but also protection from the elements during transportation. Whenever a forklift is inserted to the base of pallet, you might run the risk of tearing the stretch film. A small tear at the base of the pallet has the potential to spread throughout the entire load. Thus, in order to try to minimize this risk, it may be wise to create a film rope. Using a film rope to secure your load provides an efficient method for wrapping your products without restricting the load’s stability. Film roping is the twisting of st...

Quick Packaging News: Loading Film on the Revolution ST Pallet Wrapper

- Get link

- X

- Other Apps

Loading Film on the Revolution ST Pallet Wrapper

- Get link

- X

- Other Apps

Here we are loading the Revolution ST Pallet Stretch Wrapping Machine by Quick Pak Inc with our HYB2050 Pre-stretched Cast Machine Film. The roll is 20" wide and 5000 feet in length. I also show how to thread the film and how all the controls on the carriage work. If you need more information feel to contact us here: Quick Pak Inc 4007 North 56th Street Tampa, FL 33610 PH: 813 242 6995 FX: 813 242 6985 sales@quickpakinc.com www.quickpakinc.com

How to Load Pallet Wrap on the Revolution ST Wrapping Machine

- Get link

- X

- Other Apps

Quick Packaging News: Hand Wrapping an Over Sized Pallet with Stretch Pa...

- Get link

- X

- Other Apps

Hand Wrapping an Over Sized Pallet with Stretch Pallet Wrap

- Get link

- X

- Other Apps

How to wrap an over sized pallet with stretch film and the products used. In this video we were wrapping the Revolution ST Pallet Stretch Wrapper in the shipping crate. The size of the pallet is: 120" long x 70" wide x 42" high and the weight is 1650 Lbs. The product we used to do this are all available from Quick Pak Inc and they are: Cover-ALL 60" x 60" Clear Pallet Top Sheets. Cover-ALL Heavy Duty Metal Roll Dispenser. NWD Pallet Stretch Wrap Dispenser. 17" x 1500' HYBRiD80 Plus Stretch Hand Wrap. 3" x 2.0 x 110yd Custom Printed Carton Sealing Tape Heavy Duty 3" W Hand Tape Dispenser. More information and to buy these items: Quick Pak Inc PH: 813 242 6995 sales@quickpakinc.com www.quickpakinc.com

Quick Packaging News: Resin and Plastics Pricing News

- Get link

- X

- Other Apps

Resin and Plastics Pricing News

- Get link

- X

- Other Apps

Packaging News NEWSWIRE SNIPPETS Dear Polyethylene Customer: Effective February 1, 2017, Dow Chemical will increase the selling price of all polyethylene resins in the United States by US$0.05/lb. Products included in this price increase are as follows: - All LDPE Resins - All LLDPE Resins U.S. RESIN (LLDPE) Producer January 2017 ( Dow ) ( LyondellBasell ) NEWS RESIN PRICING Trade analyst reports in December No change in PVC resin prices (ROLLS FLAT). LLDPE resin price down $.02/lb. More info here: www.quickpakinc.com

Quick Packaging News: Plastics Pricing News from Quick Pak Inc

- Get link

- X

- Other Apps

Plastics Pricing News from Quick Pak Inc

- Get link

- X

- Other Apps

Packaging News NEWSWIRE SNIPPETS Dear Polyethylene Customer: Effective February 1, 2017, Dow Chemical will increase the selling price of all polyethylene resins in the United States by US$0.05/lb. Products included in this price increase are as follows: - All LDPE Resins - All LLDPE Resins U.S. RESIN (LLDPE) Producer January 2017 ( Read Letter ) NEWS RESIN PRICING Trade analyst reports in December No change in PVC resin prices (ROLLS FLAT). LLDPE resin price down $.02/lb. Stretch film resin pricing - LLDPE Polyethylene trading was good; volumes were above average and prices rose again. The season of holiday priced specials came and went and shelves are starting to look bare. Stretch film producers who assumed that prices would just continue lower were somewhat stunned by the lack of material availability and higher price levels. Trade Reports December 2016 LLDPE – stretch film demand picks up as distributor restocking continues. Trade Reports January 2017 More info f...

Revolution ST High Speed Pallet Stretch Wrapper for Sale

- Get link

- X

- Other Apps

You are buying = REVOLUTION ST High Speed Pallet Stretch Wrapper. This machine is built like a TANK for Industrial conditions. Quick Pak Inc is proud to introduce our new HEAVY DUTY High Speed semi automatic pallet stretch wrapper. This price competitive High Speed wrapper will give you years of trouble free operation. It will alleviate the problems associated with poorly hand wrapped pallets. The Revolution STHS represents a totally advanced design with reliable technology in a sleek efficient frame to give you a rugged machine of unmatched quality. Built Tough for Industrial applications. The Revolution STHS was designed to convert the hand wrap user over to wrapping pallets by machine and to do it up to 30 times per hour. Revolution STHS Low Profile Pallet Stretch Wrapper (High Speed Industrial Unit) Power Requirements = 120V / 1Ph / 60Hz / 20A dedicated servic...