Packaging Equipment Preventative Maintenance

Packaging Equipment Preventative Maintenance Keeps it running!

Stretch wrappers, Case Erectors, Shrink Wrappers, Case

Sealers, Strappers, Tapers- you name it, these are all very complex pieces of

packaging equipment expected to optimize your production line for efficient

packaging processes. If maintained properly, these machines can last years

without any problems or breakdowns.

Periodic maintenance is important.

Most companies search for major causes that could be

responsible for the problems, yet overlook the minor causes that contribute to

the big problem. To ensure that your business model can be upheld in the long

run, it’s important to follow up and check on the reliability of your machines.

Inspecting your machines can reduce the likelihood of any disastrous

maintenance issues that might arise unexpectedly. After all, it’s much easier, less stressful,

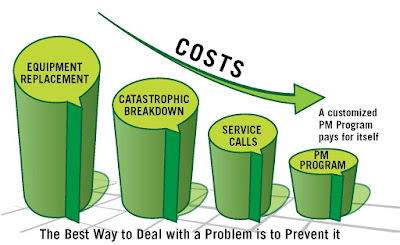

and less costly to prevent problems than it is to interrupt workflow to repair

them. A lack of preventive maintenance

is a major cause of downtime, so this is a good opportunity to catch potential

problems before they develop into larger issues and make sure your machine is

running smoothly.

While your packaging equipment doesn’t require constant

care, just a little bit of attention from time to time can go a long way toward

avoiding downtime and more costly repairs down the road. So rather than

spending money on unexpected repairs, you might want to invest in periodic

preventative maintenance program.

At Quick Pak Inc, we service end of line packaging

equipment. We perform repairs and PM’s on a variety of different packaging

equipment. We provide highly trained, well-qualified employees who are not only

concerned with maintaining your machines, but we also seek to maximize the

performance. We prides ourselves in

delivering top notch care to keep you running seamlessly for years to come.

Give us a call at (813) 242 6995 to schedule a PM or visit our website

Comments

Post a Comment