Understanding Corrugated and Box Specifications

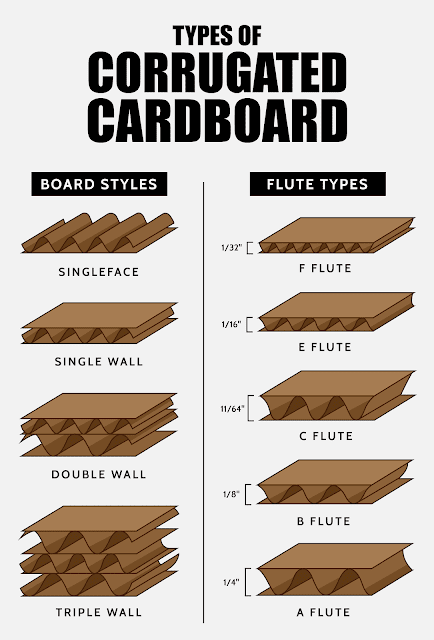

Most boxes are made from corrugated cardboard. This type of cardboard is made from a fluted or waved piece of paper sandwiched between two flat pieces of paper.

There are three main types of corrugated cardboard you’ll

come across when it comes to cartons.

Single wall – one layer of fluted board is sandwiched

between two sheets of liner board. This would make a single wall cardboard carton.

Double wall – two layers of fluting that are glued to three

layers of liner board. This would make a double wall cardboard carton, which is

stronger than using single wall alone.

Triple wall – three layers of fluting are laminated with

four liner boards. This would make a triple or tri-wall box – the most

heavy-weight and durable of all boxes.

Fluting profiles: Fluting

is the wavy or fluted piece of paper inside corrugated cardboard that helps to

strengthen the boxes. It’s what creates the stripey grain like texture you

would see when looking at a piece of cardboard.

It can vary in width and size and is often referred to by

letter e.g., “B flute”. Single wall boxes will only have one type of fluting,

but double and triple wall boxes may use multiple fluting profiles.

Board grades: The

board grade refers to the weight, quality and type of material used to make the

cardboard. Depending on the intended use of a box, the board weight will range

from 90gsm to 300gsm.

The heavier the weight of the paper, the stronger the box

will be. It’s worth noting that the GSM description of the board may relate to

the performance of the board, and not the actual weight. In other words, it has

the properties of a heavier material.

As well as the weight of the paper, you may also hear the

words “kraft” or “test”. These terms relate to if the paper used in

manufacturing is virgin material (kraft) or recycled material (test). Some

boxes may combine both kraft and test cardboard.

Contact us here at 813 242 6995 or sales@quickpakinc.com for more

corrugated information.

Comments

Post a Comment