What is Cross Linked Shrink Film?

What is Cross Linked Shrink Film?

Cross linking polymers was discovered when inventors were

searching to find a way to stabilize rubber in the mid 1800's. Charles Goodyear discovered vulcanized rubber after

years of research. The main objective was to stabilize natural rubber from

distorting in heat.

The result was Goodyear accidentally melted rubber and

sulfur on a hot stove. The combination of the two allowed the rubber to

withstand higher heats. Unknown to Goodyear at the time, the heated sulfur and

rubber changed the polymer chains within the rubber.

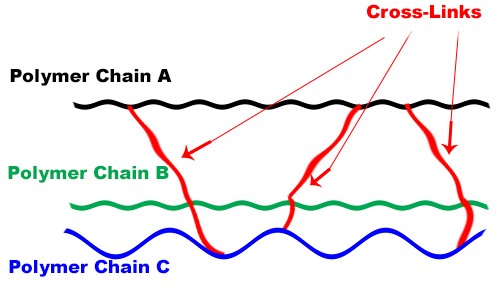

The changed polymer chains were cross linked to form a

stronger, more durable material. Since the invention of vulcanization, the

advancements in cross linking have changed tremendously. Cross linking can

be achieved with a variety of chemical additives referred to a chemical cross

linking or with irradiation.

The most common form of cross linking used for flexible

packaging materials is irradiated cross linking. Irradiated cross linking uses

electron beams that produce high energy B rays. During the irradiation process,

different bonds within the film cross link together.

The newly transformed cross-linked shrink film offers a

variety of benefits. Below is a list of detailed benefits cross linked

polyolefin shrink film offers over standard polyolefin shrink film.

Increased Puncture Resistance - One of the primary benefits of a cross linked shrink film

over standard shrink film. The cross linking of polymers increases puncture

resistance enabling users to use thinner film while still obtaining the same

strength. A thinner film offers a variety of benefits with the primary

benefit being cost. Thinner shrink film also offers better clarity, faster

sealing, and faster shrinking.

Stronger Seal Strength - The

weakest point in a shrink-wrapped package is the seal seams. A standard shrink

film does not obtain the same seal strength as a cross linked shrink film.

Stronger seals reduce damaged packages and ensures customers are purchasing a

product that has not been tampered with.

Less Residue - Over

time a shrink film will leave residue behind on the sealing wire or blade. The

left-behind residue causes the need to replace sealing wires and blades. For

fully automatic machines making thousands of seals daily, a reduced residue is

ideal for saving time and reducing the amount of replacement sealing blades.

Increased Clarity - The

ability to use a thinner film with comparable strength increases the clarity of

the shrink film. Irradiated cross linked shrink film also has less haze for

better clarity.

Longer Rolls -

Before cross-linked shrink film became popular, 60-gauge rolls were the

thinnest polyolefin shrink rolls on the market. Standard 60 gauge shrink film

rolls are 4,370 ft. long. The ability to produce thinner 45 gauge and 30 gauge

shrink film enables manufacturers to sell longer rolls. Longer rolls mean less

down time for roll changes and more time for production.

Applications

Cross linked shrink film is more expensive than standard

shrink film and is not ideal for every application. The higher price is often justified

because it is a superior product over standard shrink film. See below for

recommended applications of cross-linked polyolefin shrink film.

High Speed Shrink Wrapping - Fully automatic shrink wrap machines and semi auto machines

wrapping thousands of products per day are perfect for cross linked shrink

film. For fully automatic machines, a cross linked polyolefin shrink film will

dramatically reduce headaches.

Lightweight Products - For

light products weighing a few ounces, a cross linked shrink film may be

the way to go. A lighter 45-gauge cross linked shrink film can provide

professional packaging at less cost than a standard 60-gauge polyolefin shrink

film.

Heavy Products -

A 100-gauge cross linked shrink film is stronger and offers more seal strength than

a standard 100 gauge shrink film. A standard 100 gauge shrink film is often not

strong enough for a heavier product. Instead of going to a polyethylene shrink

film, a cross linked 100-gauge polyolefin film may be a better option to try.

Products with Sharp Edges - Because of the increased strength of a cross linked shrink

film it can often be a better option for products with sharp edges and corners.

The cross-linked film can help ensure products will reach customers without

being tampered with.

More information at www.quickpakinc.com

Comments

Post a Comment